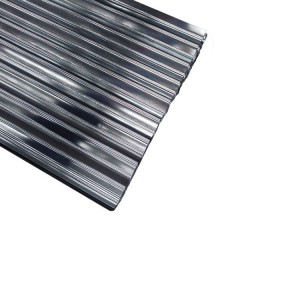

Galvanized Steel Roofing Sheet

Product description

Zinc plating is a cost-effective and effective method of preserving corrosion, and about half of the world's zinc production is used in this process. The galvanized corrugated steel sheet is made of advanced technology, with the advantages of fireproof, anti-corrosion, weather resistance, toughness, lightness, beautifulness and environmental protection. The product quality is guaranteed for at least 20 years.

The galvanized corrugated steel sheet has the advantages of light weight, high strength, good seismic performance, fast construction and beautiful appearance. It is a good building material and component, mainly used for the envelope structure, floor slab, and other structures. According to different functional requirements, the galvanized corrugated steel sheet can be pressed into a wave shape, a trapezoid or the like. It is widely used in construction projects throughout the country due to its convenient installation, moderate price and good corrosion resistance.

Product features

And because of the excellent electrochemical protection performance of the galvanized corrugated steel sheet coating. The surface of the galvanized corrugated steel sheet is evenly distributed with a layer of zinc material, which acts as an anode for the base material, that is, the alternative corrosion of the zinc material protects the use of the base material. The coating is thick and dense, the coating has strong bonding force with the steel substrate, good durability, high galvanizing capacity, long service life, no maintenance during use, simple process, strong adaptability to steel shape and high productivity. The galvanized layer is economically competitive with other protective coatings. Steel is prone to rust in air and water, and the corrosion rate of zinc in the atmosphere is only 1/15 of the corrosion rate of steel in the atmosphere. The galvanized corrugated steel sheet protects the steel plate with a dense galvanized layer to protect it from corrosion. Zinc is not easily changed in dry air, and in moist air, the surface can form a very dense film of basic zinc carbonate, which protects the internal zinc from corrosion. For the basic requirements of galvanized corrugated steel sheet, there should be no galvanization on the surface of the steel sheet, and there should be no defects such as zinc layer falling off, cracks and damage. The original board shall not have delamination; the board surface shall not be allowed to have defects such as white rust and yellow rust. The requirements for the chemical composition of galvanized corrugated steel sheet substrates are different in national standards. For example, Japan does not require it, and the United States requires it.

Product Specifications

Standard value of galvanizing amount: The amount of galvanizing is a commonly used effective method for indicating the thickness of the zinc layer of the galvanized sheet. There are two kinds of galvanizing on the two sides (ie, equal thickness galvanizing) and two kinds of galvanizing on the two sides (ie, poor thickness galvanizing). The unit of galvanizing is g/m2. Zinc layer weight code: Z100, Z200, Z275; galvanized corrugated steel sheet galvanized layer weight refers to the total amount of zinc on both sides of the steel plate, expressed in grams per cubic meter of steel plate (g / m2), such as Z100 The zinc content is not less than 100g/m2, and it is possible to distinguish by the plating layer: for example, Z12 means the total amount of double-sided plating is 120g/mm2.The protective effect of the galvanized layer in the atmosphere is proportional to the weight of the zinc layer per unit area. The weight of the zinc layer should be compatible with the required service life, thickness and forming requirements.

Product Specifications

Standard value of galvanizing amount: The amount of galvanizing is a commonly used effective method for indicating the thickness of the zinc layer of the galvanized sheet. There are two kinds of galvanizing on the two sides (ie, equal thickness galvanizing) and two kinds of galvanizing on the two sides (ie, poor thickness galvanizing). The unit of galvanizing is g/m2. Zinc layer weight code: Z100, Z200, Z275; galvanized corrugated steel sheet galvanized layer weight refers to the total amount of zinc on both sides of the steel plate, expressed in grams per cubic meter of steel plate (g / m2), such as Z100 The zinc content is not less than 100g/m2, and it is possible to distinguish by the plating layer: for example, Z12 means the total amount of double-sided plating is 120g/mm2.The protective effect of the galvanized layer in the atmosphere is proportional to the weight of the zinc layer per unit area. The weight of the zinc layer should be compatible with the required service life, thickness and forming requirements.

Product Specifications

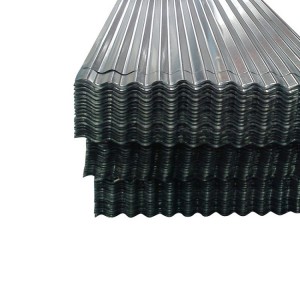

Judging from the quality requirements of galvanized corrugated steel sheet, its inspection mainly includes two aspects, one is the appearance quality, and the other is the quality inspection. Appearance quality includes packaging, size, weight, surface appearance, etc.; quality inspection includes galvanizing, mechanical properties, chemical composition, etc.

Main uses of galvanized corrugated steel sheet

1. Various roofing, wall decoration

2, interior and exterior decoration materials

3, floor structure of civil residential building

4, factory building

5, exhibition hall, sports center, power plant, railway station and other public buildings .

The quality characteristics of galvanized corrugated steel sheet are mainly

1. Beautiful appearance, reasonable design, reliable quality, easy installation and operation, high practicability, economy and market share.

2, good waterproof effect

3, widely used.

Chinese Roofing Manufacture is widely used in construction, decoration, civil building roofing, roof grille and other industries because of its good corrosion resistance, excellent processing and forming performance, low production cost and beautiful appearance. In recent years, with the gradual improvement of the quality of GI Roofing Manufacture in China, the production volume has increased year by year, and the export volume has also increased year by year. The growth rate of foreign customers is higher than the increase of production volume.