Galvalumed Steel Roofing Sheet

Product description

The corrosion resistance of Galvalumed Steel Roofing Sheet is 3 to 5 times that of galvanized steel. The more serious the corrosion, the greater the difference. If galvanized corrugated board is used, it should not be lower than Z275. Its service life is much lower than that of AZ150, so Australia Other countries clearly stipulate that if galvanized steel is used as the roof (wall), Z450 must be used. AZ150 is about 10-20% more expensive than Z275, but its corrosion resistance is 3 to 5 times higher. It can be seen that Galvalumed Steel Roofing Sheet has excellent performance and price ratio. A large number of experimental studies have been carried out abroad on the corrosion resistance of Galvalumed Steel Roofing Sheet. The research data shows that Galvalumed Steel Roofing Sheet has better corrosion resistance than galvanized corrugated board in various environments, especially in the harsh weather of coastal areas. The unique dendritic structure of the galvanized layer is the main reason for the improvement of corrosion resistance. When the aluminum-zinc-plated layer is exposed to the atmosphere, the zinc-rich region in the interdendritic network is first corroded, and the oxidation product is filled in the interstices between the dendrites, thereby reducing the corrosion rate.In particular, Galvalumed Steel is resistant to high temperature oxidation and does not undergo any discoloration or deformation when used continuously in a high temperature environment of 315 degrees Celsius.

Product application

Galvalumed Steel Roofing Sheet is an ideal building material. It has become the main force of new environmentally friendly building materials. Whether it is renovation or new construction, traditional or avant-garde design, it can meet the aesthetic appearance and practicality of the building exterior. Galvalumed Steel Roofing Sheet is also an environmentally friendly building material that does not pollute the environment. It can also be recycled 100%. It is a safe and environmentally friendly building material, which greatly improves the processing and mechanical properties of zinc and the quality is also better. The surface of the Galvalumed Steel Roofing Sheet is pre-passivated and its surface is grayed in a variety of tones that coexist with all building materials. Its raw material life span can reach 80-100 years, which gives people confidence and outlook on the appearance of the building. In recent years, in the Americas, Australia and Asia, galvanized steel sheets can be seen from private homes to public buildings such as airports, opera houses, convention centers, stadiums and museums.

Galvalumed Steel Roofing Sheet is widely used in foreign construction, and its application in China is still not very popular. However, with the rapid development of China's economy, large-scale basic public facilities throughout the country: landmark buildings, convention centers, grand theaters, stadiums, Public construction projects such as museums, cultural centers, and airports have been extensively designed and constructed. The application of the future Galvalumed Steel Roofing Sheet in the Chinese construction field will be quickly popularized and developed very well.

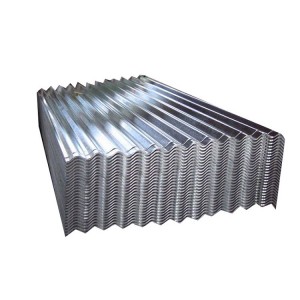

Product specifications

Galvalumed Steel Roofing Sheet's main specifications range from 0.13-0.5MM*600-1250MM Galvalumed Steel Roofing Sheet With T-Type Corrugated Bend AZ150, the main tile type is T-Type Corrugated GL Steel sheet, Wave-Type Corrugated GL Steel sheet and so on. The zinc layer is indicated by AZ, such as Galvalumed Steel Roofing Sheet AZ150.

Product advantage

The reason why it is used as roofing and wall building materials is that galvanized steel sheets have the following advantages: First, materials that have been unchanged for a long time. Building materials must be able to protect the building for a long time, and ensure that it is aesthetically pleasing and has a lasting aesthetic that has been used for decades and is timeless. Second, the ability to self-healing is strong. Double-sided pre-passivated galvanized corrugated board, but through a special impregnation process, can form a pre-passivation surface layer of different color, scratches and spots in transportation, installation or use, after natural weathering can self Heal. Third, easy to maintain. Raw zinc can be oxidized to form a surface oxide protective layer during use. Therefore, Galvalumed Steel Roofing Sheet is a UV-resistant, temperature-resistant and non-combustible natural material throughout its life cycle without special maintenance and cleaning. The galvanized corrugated board is a pleasing basket of ash-colored greed that is well coordinated with most materials. Its self-healing ability is strong, and the oxide layer not only adds structural charm over time, but also has the advantage of low maintenance cost.