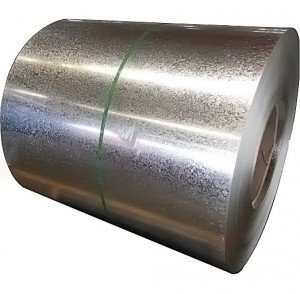

0.12-2mm thick hot dip galvanized steel coil, gi steel coil price

Overview

Standard:AiSi, ASTM, bs, DIN, GB, JIS

Grade:ASTM A653 B Type

Place of Origin:Shandong, China

Brand Name:TSONE

Model Number:DX51D

Type:Steel Coil, galvanized steel coil

Technique:Cold Rolled

Surface Treatment:galvanized

Application:pipes,purlin,air duct

Special Use:wear resistant steel

Width:100-1250mm

Length:as requirement

Tolerance:±1%

Processing Service:Bending, Welding, Decoiling, Cutting, Punching

Delivery Time:21 Days

Product Name:0.12-2mm thick hot dip galvanized steel coil, gi steel coil price

Surface:regular spangle

Packing:Standard Seaworthy Packing

Zinc Coating:30-275g/m2

Material:ASTM CS Type B

Certificate:MTC

Bundle Weight:3-8 tons

MOQ:25 tons

Coil ID:914mm

Delivery time:Within 30 Days

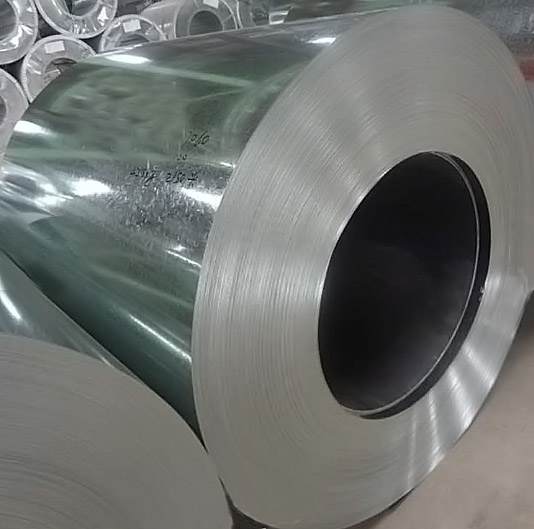

Galvanized steel is carbon steel coated with zinc. The most common galvanizing method is the hot-dip process. The hot dip process involves immersing carbon steel in a molten zinc bath (approximately 680 degrees Fahrenheit). When the material is removed from the zinc bath and cooled, it reacts with oxygen in the air. This reaction causes zinc to become part of the steel (iron-zinc alloy bond). The new surface finish seems to have a crystalline finish or a bright finish.

Although this is the most common form of galvanizing, because the thickness of the final product is not easy to control, it is usually used for previously manufactured steel. Another method of galvanizing process is continuous galvanizing.

After continuous galvanizing passes through the zinc bath, galvanizing will be performed on the surface of the continuous steel strip (coil). The coil runs at about 600 feet per minute. When the coil leaves the zinc bath, it takes away an extra layer of molten zinc. Use high-pressure air (air knife) to remove excess zinc to form the desired thickness. The material is then allowed to cool and form a shiny finish. Skip galvanized steel sheet and continuous galvanizing can control the thickness more accurately, and is usually used for steel that has not been manufactured. As the thickness of the coating increases, the risk of losing some of the coating during manufacturing or forming increases.

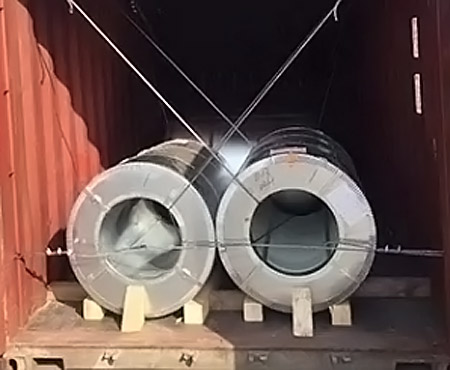

One: Waterproof paper. Waterproof paper is wrapped in the surface of a galvanized roll. Its main function is to prevent galvanized volume moisture, and avoid water vapor into the volume, then influence of hot dip galvanized coil surface. Such as zinc oxide layer when water vapor, can appear on the zinc spend turned white, affect beauty and using. This layer is necessary for the waterproof.

Two: Galvanized steel layer. It’s out of waterproof paper. During the transportation progress, it’s very easy to hit. This layer is to prevent the scratch on the surface.

Three: Edge Protection layer. It is on the both sides of the roll, and made of iron. It’s mainly to protect the edge of galvanized roll. It’s very important, if the edge of galvanized steel coil wasn’t protected, might affect the deep processing, and even damage the machine.

Four: Straps. It is used to fix the waterproof paper and galvanized iron packaging, avoid the iron fall off. For galvanized roll with the width of 1000mm to 1500mm, it should be 8 straps and transverse 4 pieces, vertical 4 pieces. It’s the best way to tighten the rolls.

Five: Tags/Marks. Mill tags will be stick on every coils outside the packages. Including: name of commodity, grade, gross weight, net weight, roll number, and information of the mill, supplier information, etc. It’s will be helpful for clients to find the right rolls against the packing list.

With better protection reinforcement mode,and 100% meet the shipping requirements,100% protect the cargo from being damaged by violent shake. With fast delivery and always serve your heart and soul.

Q: Are you factory or trading company?

A: We are manufacturer and trader, sincerely welcome you visit our factory.

Q: Why choose us?

A: Our company have been in steel business for more than ten years, we are internationally experienced, professional, and we can provide variety of steel products with high quality to our clients

Q: Can provide OEM/ODM service?

A: Yes. Please feel free to contact us for more details discuss.

Q: How is your Payment Term?

A:One is 30% deposit by TT before production and 70% balance against copy of B/L; the other is Irrevocable L/C 100% at sight.

Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

Q: Can you provide sample?

A: Yes, for regular sizes sample is free but buyer need to pay freight cost.