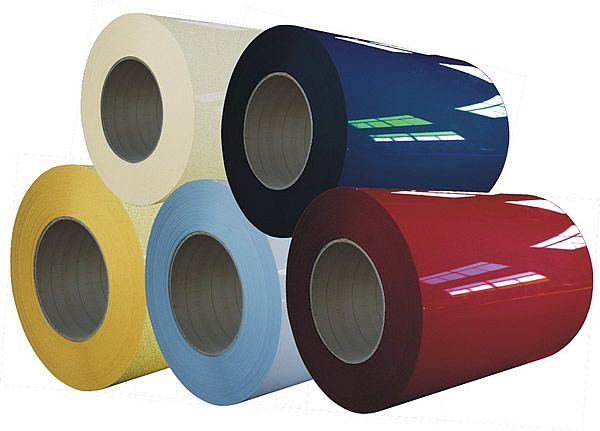

Color-coated boards provide new raw materials for the construction industry, shipbuilding industry, automobile manufacturing industry, home appliance industry and electrical industry, and have achieved good results such as replacing wood with steel, energy saving and emission reduction. Below taishaninc will introduce its process flow.

1. Color-coated steel plate is a product made of cold-rolled steel plate and galvanized steel plate as the base material, which is made by surface pretreatment (degreasing, cleaning, chemical conversion treatment), continuous coating (roller coating method), baking and cooling.

2. The main production process of the ordinary two-xu-two-drying continuous color coating unit is: uncoiling-pretreatment-coating-baking-post-processing and coiling.

3. The color plate produced by the cold-rolled base plate has a smooth and beautiful appearance and has the processing performance of the cold-rolled plate; however, any slight scratches on the surface coating of the color-coated plate will expose the cold-rolled base material to the air, resulting in exposed Red rust appears on iron. Therefore, such products should only be used in less demanding temporary isolation measures and indoor materials

1、 Hot dip galvanized color coated steel plate

The product obtained by coating hot-dip galvanized steel plate with organic coating is hot-dip galvanized steel plate. The organic coating on the surface of hot-dip galvanized steel plate not only has a protective effect of zinc, but also plays a role in heat insulation and rust prevention, with a longer service life than hot-dip galvanized steel plate. The zinc content of hot-dip galvanized substrate is generally 180g/m2 (on both sides), and the zinc content of external hot-dip galvanized substrate is 275g/m2.

2、 Hot dip aluminum zinc coated color coated plate

According to needs, hot-dip aluminum zinc plated steel plates can also be used as color coated substrates (55% aluminum zinc and 5% aluminum zinc). Galvanized color coated sheet uses galvanized sheet as the substrate, and the product obtained by organic coating baking is galvanized. Due to the thin zinc layer of galvanized sheet, the zinc content is usually 20/20g/m2, so this product is not suitable for outdoor wall and roof production. However, due to its beautiful appearance and excellent processing performance, it can be mainly used in household appliances, audio systems, steel furniture, interior decoration, etc

In summary, color coated panels have been widely used and have made significant contributions to industry, driving the rapid development of industry and economy.

Post time: Sep-27-2023