Short Lead Time for Geotextile Retaining Wall - Dewating Tube Durability Geotextile Geobag Harbors – Taishan

Short Lead Time for Geotextile Retaining Wall - Dewating Tube Durability Geotextile Geobag Harbors – Taishan Detail:

Overview

Quick Details

| Warranty | 5 years |

| After-sale Service | Online technical support |

| Project Solution Capability | Others |

| Application | Outdoor |

| Design Style | Industrial |

| Place of Origin | Shandong, China |

| Model Number | GB |

| Geotextile Type | Non-Woven Geotextiles |

| Type | GEOTUBE |

| Product name | Geotube |

| type | earthwork product |

| function | Water Permeable |

| size | 3x4ft,3.5x7ft,6x6ft,7.5x10ft |

| width | 2-6m |

| application1 | flood control, erosion control |

| application2 | embankment construction |

| application3 | river training works, sea wall construction |

| Material | PP(polypropylene) PET (polyester) |

| weight | 100-1000g/sqm |

Supply Ability : 30000 Square Meter/Square Meters per Month

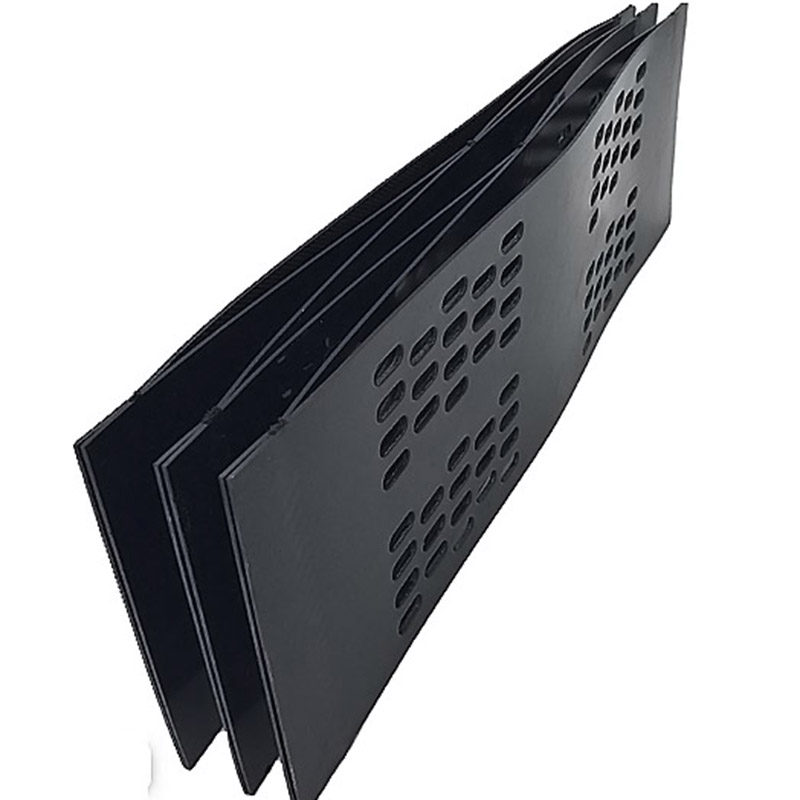

Plastic PP Geogrid

PP Biaxial Geogrid is manufactured from Polypropylene, from the process of extruding, longitudinal stretching and transverse stretching.

PP Uniaxial Geogrid is an integrally formed structure, which especially designed for soil stabilization and reinforcement

applications.

Product Details

|

Item |

Technical Data |

||||||||

|

Nominal strength KN/m |

50 |

65 |

80 |

100 |

120 |

140 |

160 |

180 |

200 |

|

≥Breaking strength in CD KN/m |

50 |

65 |

80 |

100 |

120 |

140 |

160 |

180 |

200 |

|

≥Breaking strength in MD KN/m |

0.7 times of breaking strength in MD |

||||||||

|

≤Nominal elongation % |

35in MD, 30in CD |

||||||||

|

≥Tear strength in MD and CD KN |

0.8 |

1.1 |

1.3 |

1.5 |

1.7 |

1.9 |

2.1 |

2.3 |

2.5 |

|

≥CBR mullen burst strength KN |

4.0 |

6.0 |

8.0 |

10.5 |

13.0 |

15.5 |

18.0 |

20.5 |

23.0 |

|

vertical permeability cm/s |

Kx(10-2—10-5) K=1.0-9.9 |

||||||||

|

Sieve size O90(o95) mm |

0.05-0.5 |

||||||||

|

Width variation % |

-1 |

||||||||

|

Woven bag thickness variation under irrigate % |

±8 |

||||||||

|

Woven bag variation in length and width % |

±2 |

||||||||

|

Sewing Strength KN/m |

80% of nominal strength |

||||||||

|

Unit weight variation % |

-5 |

||||||||

|

Mass per unit g/㎡ |

200 |

260 |

320 |

390 |

460 |

530 |

600 |

680 |

760 |

Product Advantages

The Geotextile Tube Bag dehydration technology is an effective technology and a solution that has been proven safe for dehydration by many research centers around the world. It is made of high-performance, special polypropylene monofilament, flat yarn or split film yarn for cloth processing and special sewing.

Solids are contained inside the Geotube dewatering unit, Easy removal and disposal solids from polluted water.

Efficient, versatile and environmental friendly solution reduces carbon. High effluent discharge rate with clear filtrate that can be recirculated through the system.

Custom-sized containers saves expensive and limited land space, Geotube dewatering unit can be cut open, exposing highly dewatered solids that can be easily excavated and transported away.

Cost effective, low maintenance and saves time. Reliable in all weather conditions and reduces risks in operational safety.

application

Product detail pictures:

Related Product Guide:

Our advancement depends over the highly developed devices, excellent talents and continually strengthened technology forces for Short Lead Time for Geotextile Retaining Wall - Dewating Tube Durability Geotextile Geobag Harbors – Taishan , The product will supply to all over the world, such as: Estonia, Singapore, Milan, Our company has a skillful sales team, strong economic foundation, great technical force, advanced equipment, complete testing means, and excellent after-sales services. Our items have beautiful appearance, fine workmanship and superior quality and win the unanimous approvals of the customers all over the world.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!