Definition and Composition

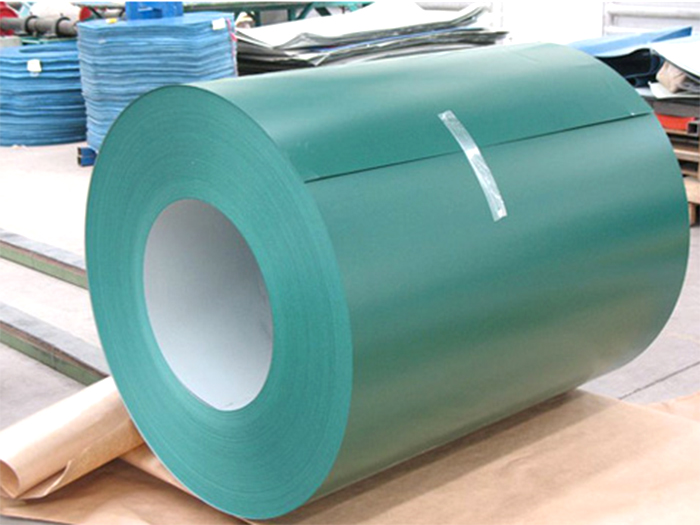

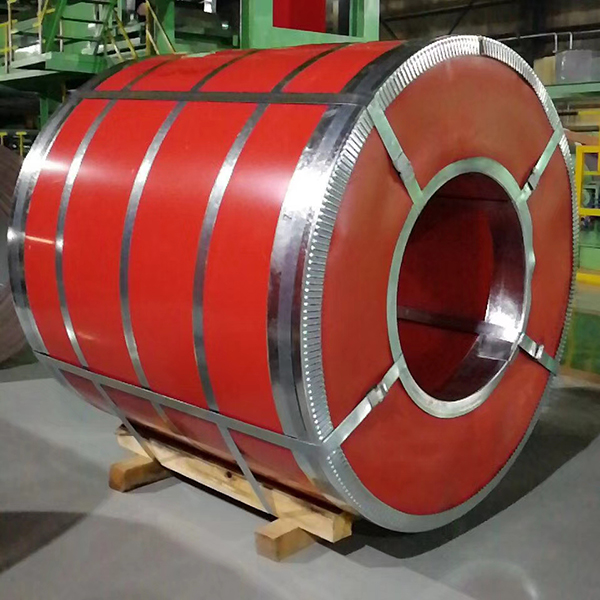

Color coated coil: It is a product made by applying one or more layers of organic coating to cold-rolled or hot-dip galvanized substrates after surface pretreatment, and then baking and curing them. It has good corrosion resistance, decorative and processing properties.

Color steel coil: generally refers to color coated steel plate coil, similar to color coated coil, but the substrate of color steel coil is usually cold-rolled steel plate or galvanized steel plate, and the coating can be different types of coatings such as polyester, silicon modified polyester, polyvinylidene fluoride, etc.

Performance characteristics

Corrosion resistance: Due to coating protection, both color coated coils and color steel coils can effectively resist the erosion of substances such as water vapor, oxygen, acid and alkali in the atmosphere, extending their service life. For example, in some industrial plants, using color coated coils or color steel coils as roof panels can prevent rusting for a long time.

Decorative: They can provide rich colors and surface textures to meet different architectural and decorative needs. Colorful color steel coils are often used on the exterior of commercial buildings to create a unique appearance.

Good processing performance: easy to perform cutting, bending, stamping and other processing operations, can be made into various shapes of components, suitable for different building structures and purposes.

application area

Construction industry: widely used in roof, wall, sandwich panel, etc., such as roof and wall enclosure systems for large industrial plants, warehouses, sports venues, exhibition halls, and other buildings.

Household appliance industry: Used for the outer shell of refrigerators, air conditioners, washing machines and other household appliances, which is both beautiful and protective.

• Other fields: It can also be used for carriage boards, container boards in the transportation industry, as well as decorative boards in the furniture industry.

Key points for purchasing

• Substrate quality: Check whether the thickness of the substrate meets the requirements, whether the surface is flat and smooth, and whether there are obvious defects such as scratches and rust spots.

Coating performance: Understand the type, thickness, adhesion and other performance indicators of the coating to ensure that it has good weather resistance, corrosion resistance and wear resistance. For example, for color coated coils or color steel coils used outdoors, a polyvinylidene fluoride coating with good weather resistance should be selected.

Brand and manufacturer: Choose well-known brands and manufacturers with good reputation, as their product quality and after-sales service are more guaranteed.

Maintenance

• Avoid surface scratches: During handling and installation, be careful to prevent sharp objects from scratching the surface coating of the color coated coil or color steel coil, so as not to affect its corrosion resistance and aesthetics.

• Regular cleaning: Regularly wipe the surface with a clean soft cloth or neutral cleaner to remove dust, dirt, etc., and keep its appearance clean.

Timely repair of damages: If any damage or detachment of the coating is found, it should be repaired in a timely manner to prevent the substrate from rusting when exposed to air.

Post time: May-16-2025