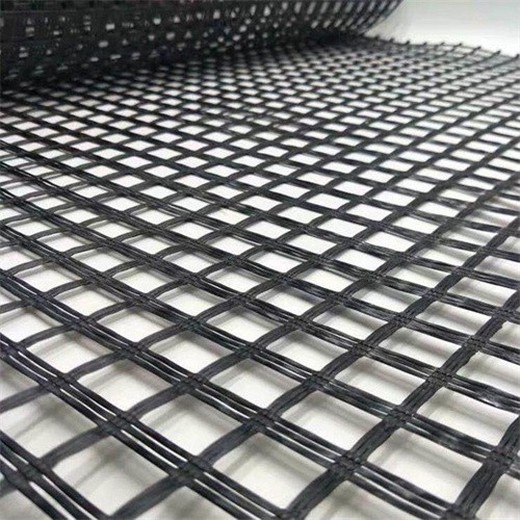

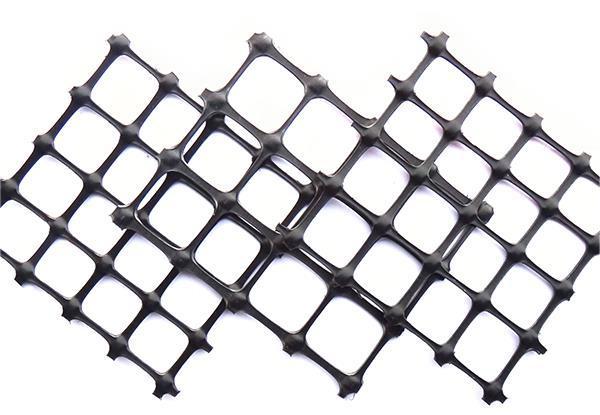

In engineering applications, the waterproof performance of bidirectional geogrids can be improved through the following methods:

Surface coating treatment

Waterproof coatings such as polyurethane, epoxy resin, etc. can be applied to the surface of bidirectional geogrids. These coatings can form a continuous and dense waterproof membrane on the surface of geogrids, effectively preventing moisture infiltration. During construction, it is necessary to ensure that the coating evenly covers the geogrid to avoid omissions or uneven thickness. At the same time, suitable coatings should be selected according to the engineering environment and requirements. For example, in humid environments, coatings with good water resistance should be selected.

Another method is to use hot melt coating technology, which heats and melts the hot melt waterproof material and applies it to the surface of the geogrid. The coating formed by this method is closely integrated with the geogrid, with more reliable waterproof performance and good high and low temperature resistance.

Composite use with waterproofing membrane

Combining bidirectional geogrids with waterproofing membranes is an effective way to improve waterproofing performance. Firstly, lay a two-way geogrid to enhance the soil structure through its reinforcement effect, and then lay waterproof rolls on it, such as SBS modified asphalt waterproof rolls, polymer waterproof rolls, etc. Waterproof membrane can provide a good waterproof barrier, while geogrid provides a stable base for the membrane to prevent damage due to soil deformation.

During the composite process, attention should be paid to the bonding effect between the two. Special adhesives can be used to firmly bond geogrids and waterproofing membranes together, or mechanical fixation methods can be used, such as using nails to fix the two to the base layer, to ensure that they will not separate during engineering use and thus ensure the integrity of the waterproofing system.

Optimize the laying process

When laying bidirectional geogrids, it is necessary to ensure that the laying surface is flat, avoid unevenness or sharp objects, and prevent the geogrid from being punctured under pressure, which may affect its waterproof performance. At the same time, attention should be paid to the overlap width and connection method of the geogrid to ensure a tight connection. Generally speaking, the overlap width should not be less than the design requirements, and special connection tools or adhesives should be used for connection to reduce gaps and minimize the possibility of water leakage.

For the installation environment, drainage measures should be taken to avoid laying geogrids in the presence of accumulated water. After the installation of geogrid, the construction of the upper structure should be carried out in a timely manner to reduce its exposure time to the external environment, prevent aging and damage caused by long-term exposure, and affect its synergistic waterproof effect with other waterproof materials.

Through the above methods, the waterproof performance of bidirectional geogrids in engineering applications can be improved to a certain extent, making them better meet the waterproof requirements of the project.

Post time: May-29-2025