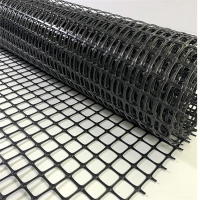

Geogrid is a popular geotechnical material nowadays, which can be reused due to its low price and good practicality. Steel plastic geogrid is composed of steel plastic reinforced strips combined by innovative technology. Due to the regular coarse patterns on the surface of this product, it is laid in the replacement soil layer and bears huge stress resistance and friction with the fill soil, which overall limits the shear, lateral extrusion, and uplift of the foundation soil.

Due to the high stiffness of the reinforced soil cushion layer, it is conducive to the diffusion and uniform transmission of the upper foundation load, distributed to the underlying soft soil layer, and effectively improves the bearing capacity of the foundation. Due to the role of the reinforced soil cushion layer, it increases the overall stiffness of the foundation within the compression layer range, which is conducive to adjusting the deformation of the foundation. The reinforced soil composite cushion layer formed by using steel plastic reinforced geogrids is a flexible structure that can absorb earthquake energy well, so its seismic performance is good.

Geogrid exerts its reinforcement effect through tensile stress:

The influence of soil conditions on the reinforcement effect of geogrids. When the lateral deformation of the soil is very large, the outer surface of the embankment will bulge severely. Geogrids can fully exert their reinforcement performance. Below, without changing the compression mold of the soil, only the effective strength index of the soil is changed to control the plastic geogrid performance of the soil, in order to analyze the adaptability of geogrids to different soil conditions.

Geogrids mainly exert their reinforcement effect through tensile stress, and only when the soil undergoes uplift and a large amount of lateral extrusion can the geogrid generate tensile strain, thereby generating tensile stress. The lateral deformation of the soil is limited by the frictional force between the geogrid and the reinforcement filler, achieving the effect of changing the stress state of the foundation. Therefore, it cannot be simply said whether geogrids can reduce uneven deformation of the foundation or how significant the reinforcement effect is, but it needs to be targeted at specific soil conditions.

Generally speaking, the soil conditions in soft soil areas are poor, and the soil fluidity is relatively high. Under the action of embankment load, significant lateral deformation occurs. Therefore, adding materials such as plastic geogrids and steel plastic geogrids can greatly improve uneven deformation.

The geogrid factory teaches you how to use geogrids in construction:

During transportation and storage of geogrids, they must not be contaminated, exposed to rain, or damaged. They should be kept away from sources of fire, and there should be no corrosive media such as acids or alkalis around them. They should not be exposed to prolonged sunlight or kept upright. When materials enter the site, random inspections should be conducted. During construction, there should be a dedicated person to inspect and clear the foundation, the direction of material placement, the joints or overlaps of materials, and the connection between materials and structures at any time. Each completed process should be inspected and accepted in a timely manner according to the design requirements. Only after passing the inspection can the next process be carried out.

The construction site should be flat and clean to prevent damage to the geomembrane; The laying should be smooth and the tightness should be moderate. The overlap width for laying on uneven ground, soft soil, and underwater should be appropriately increased. Laying personnel are not allowed to wear hard soled shoes during operation.

Try to use a wide width to minimize the number of seams during membrane construction; The weight of each roll of material should not exceed 1 ton; When connecting membranes, the same type of geomembrane should be used. Polyester woven geogrid for high dams should be laid perpendicular to the dam axis, while for low dams, it should be laid parallel to the dam axis to reduce the amount of splicing; The seam should be parallel to the direction of tension as much as possible. Vertical plastic paving should be strictly constructed according to the process requirements, and the speed of PE plastic film application should be fast to prevent the collapse of the groove and affect the paving effect.

Post time: Apr-22-2025