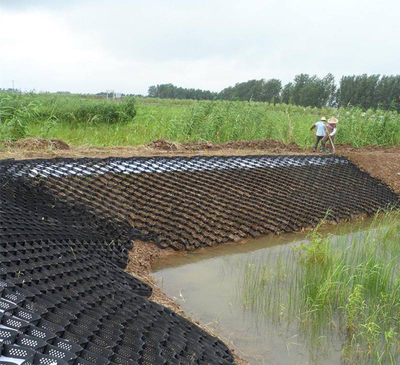

As a key material for roadbed reinforcement and slope protection, the laying quality of geogrid directly determines the stability of the project. However, in actual construction, hidden dangers often arise due to improper operation. The following are 8 typical incorrect laying methods.

Inadequate foundation treatment is the primary common mistake, and some construction projects, in order to meet the schedule, fail to remove gravel, weeds, sharp debris from the foundation, or directly lay the foundation without leveling and compacting it. This type of substrate has protruding hard objects that can puncture the cells under later loads. At the same time, loose substrates can easily cause uneven stress on the cells, leading to local settlement or deformation and loss of reinforcement effect.

Irregular unfolding and splicing of cells are also common. Firstly, the cells in the cells are not fully stretched according to the design requirements during unfolding, resulting in small cell sizes and insufficient effective force area, which cannot exert the three-dimensional constraint effect; The second issue is that specialized connectors were not used during splicing, and only simple overlapping or fixing with ordinary iron wire was used. The strength of the splicing area is insufficient, and it is prone to cracking and falling off under external forces, resulting in overall instability of the cell.

Errors in laying direction and fixing method are also common, and the angle of grid laying is not adjusted according to the direction of roadbed stress and slope direction. For example, the roadbed under lateral stress is laid longitudinally, which reduces its shear resistance; When fixing, only the edges are simply compacted without using U-shaped nails, anchor rods, etc. to fix them at intervals, or the fixing depth is insufficient. The grid is prone to displacement and arching during filling and rolling, which can damage the overall structure.

Improper filling and compaction operations are key errors that affect the quality of the project. Firstly, the filling sequence is chaotic, and the filling is not layered from the middle to both sides of the grid, resulting in the grid being distorted under stress; The second issue is that the particle size of the filler used is too large, exceeding the cell size of the cell and unable to fill the cell to form effective constraints; The third reason is that the compaction equipment is too heavy or the compaction speed is too fast, directly crushing the unfilled space chamber, causing deformation, damage, or insufficient compaction degree of the cell, resulting in settlement in the later stage.

In addition, ignoring the setting of drainage systems, not reserving expansion and contraction for slope paving, and arbitrarily cutting grid cells are also common errors. If geotextile is not laid on the bottom layer of the grid to guide drainage, it is easy to cause the base to accumulate water and soak the grid, accelerating aging; When laying the slope, temperature changes and soil settlement were not taken into account, resulting in lattice cracking; When cutting, the material was not accurately cut according to the actual size, resulting in gaps or excessive overlap at the joints, which affects the transmission of force.

These incorrect laying methods may seem to save time, but in reality, they significantly reduce the durability of the project and can easily cause safety accidents such as roadbed settlement and slope landslides. It is necessary to strictly follow the construction specifications, control the entire process from base treatment, grid laying to filling and compaction, and avoid hidden dangers.

Post time: Nov-17-2025