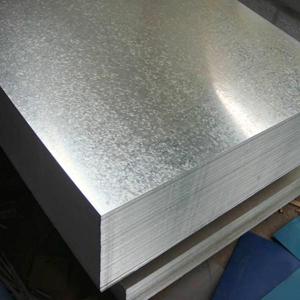

Galvanized sheet metal is a common metal material, mainly used in construction, manufacturing, transportation and other fields. It is highly favored due to its advantages of corrosion resistance, wear resistance, aesthetics, and durability. This article will explore the manufacturing process, application areas, and environmental issues of galvanized sheet metal.

Firstly, let’s understand the manufacturing process of galvanized sheet metal. Galvanized steel plate achieves anti-corrosion effect by coating a layer of zinc on the surface of the steel plate. This process is called hot-dip galvanizing.

The hot-dip galvanizing process mainly consists of two steps: preparation work and galvanizing process. In the preparation work, the steel plate needs to be cleaned first to remove surface oil stains and impurities. Then, immerse the steel plate into a galvanizing tank containing molten zinc, and the high-temperature molten zinc reacts chemically with the surface of the steel plate to form a layer of zinc iron alloy. This layer of zinc iron alloy has good corrosion resistance and can effectively protect the steel plate from oxidation and corrosion.

Galvanized sheet has a wide range of applications. Firstly, it is widely used in the field of architecture for roofs, walls, floors, and other areas. Due to its excellent corrosion resistance and ability to withstand various harsh weather conditions, galvanized sheet is highly suitable for external protection of buildings. Secondly, in the manufacturing industry, galvanized sheet metal is often used to manufacture automobiles, household appliances, electronic products, etc. It can provide good mechanical performance and appearance effect, while also extending the service life of the product. In addition, galvanized sheet metal is also used in the field of transportation, such as manufacturing ships, railway vehicles, etc. It can effectively prevent the corrosion of steel in humid environments, thereby improving the safety and reliability of transportation vehicles.

However, there are also some environmental issues in the production process of galvanized sheet. Firstly, the hot-dip galvanizing process generates a large amount of exhaust gas and wastewater. These exhaust gases and wastewater contain a large amount of heavy metals and organic matter, causing certain pollution to the environment. Secondly, the hot-dip galvanizing process requires a large amount of energy consumption, resulting in energy waste and increased carbon emissions. In order to solve these problems, some enterprises have begun to adopt new galvanizing processes, such as cold galvanizing and electroplating galvanizing. These processes can reduce the discharge of exhaust gas and wastewater, lower energy consumption, and thus reduce the impact on the environment.

In addition, environmental protection issues should also be taken into account during the use of galvanized sheets. Firstly, galvanized sheets may generate waste during use, such as cut waste and used old materials

board. These wastes should be classified and recycled to reduce resource waste. Secondly, galvanized sheets may be affected by mechanical wear and corrosion during use, resulting in damage to the galvanized layer. Once the galvanized layer is damaged, the steel plate will be exposed to external oxygen and moisture, making it prone to corrosion. Therefore, timely repair and maintenance of the galvanized layer of galvanized sheet is very important.

In summary, galvanized sheet metal is a metal material with broad application prospects. It forms a layer of zinc iron alloy on the surface of the steel plate, which has good corrosion resistance and can effectively protect the steel plate from oxidation and corrosion. Galvanized sheet has been widely used in fields such as construction, manufacturing, and transportation. However, there are also some environmental issues that need to be taken seriously in the production and use of galvanized steel sheets. By adopting new galvanizing processes and strengthening the maintenance and repair of galvanized sheets, the impact on the environment can be reduced, achieving sustainable development.

Post time: Jun-02-2025